Eco-conscious product promotion

Eco-conscious product promotion

Source the latest eco-conscious innovations in technical foam and industrial bonding

Legislation, climate conservation, and customer preference are driving businesses to be conscious of environmental factors. However, with many options on the market, it can be challenging to find the right path. Reducing energy consumption, adopting bio-content, exploring end-of-life options, recycling, material reduction... the list is endless. We have collaborated with our exhibitors to help promote products and services that could be part of your eco-conscious strategy.

Spot our eco-conscious logo

Disclaimer: participating exhibitors are responsible for justifying the viability of the eco-consciousness of their products. You must pre-register for free to access our face-to-face show where the below products will be displayed at exhibitor stands.

WAVE FOAMER with Radiofrequency (RF)

Parts made of particle foam have ever since been produced by heating with steam. The production process generates friction and heat. Energy used is often lost as unused waste heat. The mould must be cooled down by adding water. With the RF process, the energy is transferred directly into the moulded part thus saving up to 90% energy. RF eliminates the need to install a steam generation plant and cooling tower. Shape moulding machines can be placed at customer’s premises. Transport distances reduce, parts are produced just in time. Compared to the standard process, the CO2 footprint improves by up to 70%.

WAVE FOAMER with Radiofrequency (RF)

Parts made of particle foam have ever since been produced by heating with steam. The production process generates friction and heat. Energy used is often lost as unused waste heat. The mould must be cooled down by adding water. With the RF process, the energy is transferred directly into the moulded part thus saving up to 90% energy. RF eliminates the need to install a steam generation plant and cooling tower. Shape moulding machines can be placed at customer’s premises. Transport distances reduce, parts are produced just in time. Compared to the standard process, the CO2 footprint improves by up to 70%.

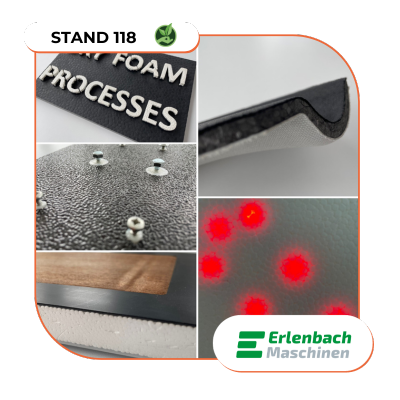

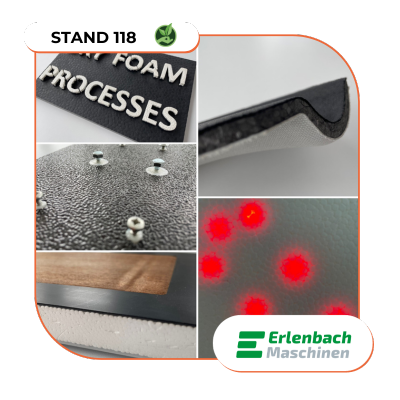

Dry Foaming

Rising energy costs and growing demands on materials, equipment, and composites were the basis for this new process technology. Together with its development partner FOX Velution, Erlenbach offers the solution to all these challenges - with the Dry Particlefoam Process Equipment, the usual limits of steam-based particle foam processing can be easily exceeded, and new materials processed and applications created. Learn more about this fascinating way to process particle foams - without steam-based equipment - and thus in a particularly sustainable way.

Dry Foaming

Rising energy costs and growing demands on materials, equipment, and composites were the basis for this new process technology. Together with its development partner FOX Velution, Erlenbach offers the solution to all these challenges - with the Dry Particlefoam Process Equipment, the usual limits of steam-based particle foam processing can be easily exceeded, and new materials processed and applications created. Learn more about this fascinating way to process particle foams - without steam-based equipment - and thus in a particularly sustainable way.

Sustainable foam materials - the alternative

In the past, polyurethane (PUR) foams were produced primarily from raw materials based on crude oil. Today, there are various methods for producing foam materials with a steadily increasing sustainable content. These techniques reduce the proportion of fossil components, lower climate-damaging CO2, or utilise various recycling options to decrease the use of new resources by means of a circular economy. Together with suppliers and project partners, Pahlke has been working with conviction for many years on the development and marketing of foam materials with sustainable components and their sustainable processing. For more information visit our website here and specific sustainable solutions here.

Sustainable foam materials - the alternative

In the past, polyurethane (PUR) foams were produced primarily from raw materials based on crude oil. Today, there are various methods for producing foam materials with a steadily increasing sustainable content. These techniques reduce the proportion of fossil components, lower climate-damaging CO2, or utilise various recycling options to decrease the use of new resources by means of a circular economy. Together with suppliers and project partners, Pahlke has been working with conviction for many years on the development and marketing of foam materials with sustainable components and their sustainable processing. For more information visit our website here and specific sustainable solutions here.

Biobased Polylactic Acid (PLA)

Useon offers sustainable solutions for the packaging industry by utilizing polylactic acid (PLA) to replace conventional disposable packaging materials like EPS, EPE, and EPP. Our raw material production and product applications align with the principles of sustainable development. Our products are entirely biodegradable, empowering our customers to achieve their sustainability objectives. In comparison to other paper-based packaging options, our PLA foam beads exhibit exceptional functionality. These beads can be molded into a variety of foam products across diverse industries, including home appliances, food, electronics, luxury packaging, and more.

Biobased Polylactic Acid (PLA)

Useon offers sustainable solutions for the packaging industry by utilizing polylactic acid (PLA) to replace conventional disposable packaging materials like EPS, EPE, and EPP. Our raw material production and product applications align with the principles of sustainable development. Our products are entirely biodegradable, empowering our customers to achieve their sustainability objectives. In comparison to other paper-based packaging options, our PLA foam beads exhibit exceptional functionality. These beads can be molded into a variety of foam products across diverse industries, including home appliances, food, electronics, luxury packaging, and more.

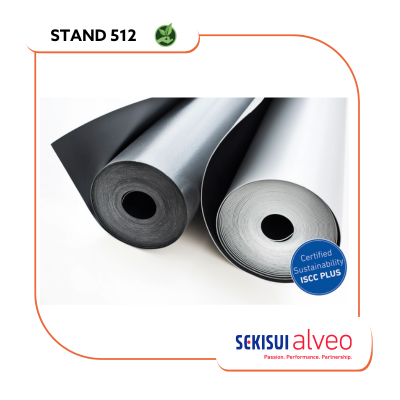

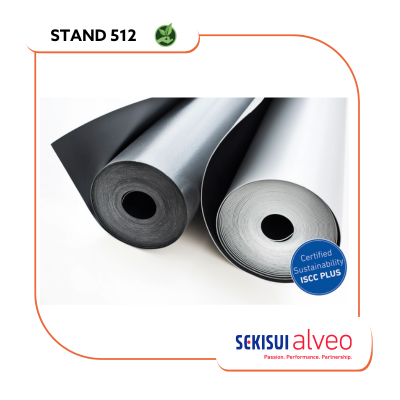

Certified sustainability foam

Sekisui Alveo shows a wide range of high performance polyolefin foam solutions for adhesive tape, automotive, industrial, construction and flooring underlay applications. The polyolefin-based foams are lightweight and free of harmful substances. Due to their durability, they contribute significantly to sustainability. The products can be manufactured from up to 100% natural and sustainable raw materials according to the ISCC PLUS mass balance approach. Sekisui Alveo will also show a new generation of sustainable halogen-free flame retardant foams. These products are currently available for the product lines Alveolit TA and Alveolit TL in various densities and thicknesses. The traditional versions of these foams currently remain available as well.

Certified sustainability foam

Sekisui Alveo shows a wide range of high performance polyolefin foam solutions for adhesive tape, automotive, industrial, construction and flooring underlay applications. The polyolefin-based foams are lightweight and free of harmful substances. Due to their durability, they contribute significantly to sustainability. The products can be manufactured from up to 100% natural and sustainable raw materials according to the ISCC PLUS mass balance approach. Sekisui Alveo will also show a new generation of sustainable halogen-free flame retardant foams. These products are currently available for the product lines Alveolit TA and Alveolit TL in various densities and thicknesses. The traditional versions of these foams currently remain available as well.

Trocellen’s NATURELOOP portfolio

Trocellen’s NATURELOOP portfolio is designed with the goal of minimizing negative environmental impacts and promoting long-term ecological balance.These applications aim to meet the environmental needs of our planet without compromising the ability to provide high-quality, stable performance, lightweight and long-lasting solutions. NATURELOOP brand incorporates sustainable products and materials: New products at Trocellen are developed using Ecodesign principles, Trocellen RePe solutions are made with recycled polyethylene, which contributes to reducing the environmental footprint of the product, TR-EEcell is Trocellen’s biobased foam. Products contain raw materials derived from biomass, still look and behave like fossil-based plastic products.

Trocellen’s NATURELOOP portfolio

Trocellen’s NATURELOOP portfolio is designed with the goal of minimizing negative environmental impacts and promoting long-term ecological balance.These applications aim to meet the environmental needs of our planet without compromising the ability to provide high-quality, stable performance, lightweight and long-lasting solutions. NATURELOOP brand incorporates sustainable products and materials: New products at Trocellen are developed using Ecodesign principles, Trocellen RePe solutions are made with recycled polyethylene, which contributes to reducing the environmental footprint of the product, TR-EEcell is Trocellen’s biobased foam. Products contain raw materials derived from biomass, still look and behave like fossil-based plastic products.

Bio Based and 100% recyclable Packaging Foam

Foam Engineers is the leading UK based foam converter offering eco foam solutions with a focused approach to reducing our impact on the environment. We convert a comprehensive range of eco materials including bio-based content, biodegradable, 30% recycled content, wood pulp, corn starch and full recyclability foams. Our wood fiber and wood pulp-based foams are entirely plastic free, lightweight, provide excellent technical, cushioning and insulating properties, can be converted into many complex shapes and end products and are optimal for replacing PU plastic foams. Wood foams can be recycled as paper globally in doorstep recycling streams, are home compostable and will biodegrade.

Bio Based and 100% recyclable Packaging Foam

Foam Engineers is the leading UK based foam converter offering eco foam solutions with a focused approach to reducing our impact on the environment. We convert a comprehensive range of eco materials including bio-based content, biodegradable, 30% recycled content, wood pulp, corn starch and full recyclability foams. Our wood fiber and wood pulp-based foams are entirely plastic free, lightweight, provide excellent technical, cushioning and insulating properties, can be converted into many complex shapes and end products and are optimal for replacing PU plastic foams. Wood foams can be recycled as paper globally in doorstep recycling streams, are home compostable and will biodegrade.

Bio-qualities and closed production cycle

The portfolio of the "Experts in foam" includes cellular rubber and cellular polyethylene in bio-quality. Recyclates are recovered from the production surpluses of these materials, which are mainly manufactured from sustainable raw materials, and returned to the production cycle as solid or liquid recyclate. With an additional option for upcycling production surpluses from the production of conventionally manufactured PE foams, the production cycle is now completely closed. While production surplus from cellular rubber is often used as flooring, e.g. on tartan tracks or playgrounds, cellular polyethylene residues are used as a sustainable filler in packaging applications. KÖPP thus now produces 100% sustainably.

Bio-qualities and closed production cycle

The portfolio of the "Experts in foam" includes cellular rubber and cellular polyethylene in bio-quality. Recyclates are recovered from the production surpluses of these materials, which are mainly manufactured from sustainable raw materials, and returned to the production cycle as solid or liquid recyclate. With an additional option for upcycling production surpluses from the production of conventionally manufactured PE foams, the production cycle is now completely closed. While production surplus from cellular rubber is often used as flooring, e.g. on tartan tracks or playgrounds, cellular polyethylene residues are used as a sustainable filler in packaging applications. KÖPP thus now produces 100% sustainably.

MPG’s revolutionary technology enables durable and sustainable bonding

MPG helps improving adhesion with its revolutionary molecular coating technology that binds organic chemistry to surfaces by injecting it through a cold atmospheric plasma flow. It enables adhesive bonding of inert materials like polyolefins or fluorinated polymers or glass, as well as anti-stick and other functionalities. By replacing chemical energy with a small amount of electrical power MPG's machines can run solvent-free process and significantly reduce the consumption of chemicals.

MPG’s revolutionary technology enables durable and sustainable bonding

MPG helps improving adhesion with its revolutionary molecular coating technology that binds organic chemistry to surfaces by injecting it through a cold atmospheric plasma flow. It enables adhesive bonding of inert materials like polyolefins or fluorinated polymers or glass, as well as anti-stick and other functionalities. By replacing chemical energy with a small amount of electrical power MPG's machines can run solvent-free process and significantly reduce the consumption of chemicals.

Debonding Adhesive for Mattress Recycling

Foam mattresses bonded with our SIMALFA® debonding adhesive can now be completely returned to the raw materials cycle. The most important thing is that our adhesive is designed in such a way that the foam layers of the mattresses can be completely debonded from each other again. This process has the advantage of not only making it possible to recycle the mattress in the traditional way, but our SIMALFA® adhesive even makes it possible to upcycle the raw materials. SIMALFA® has always been at the forefront in developing foam bonding adhesives. With our new SIMALFA® debonding adhesive we just did it again.

Debonding Adhesive for Mattress Recycling

Foam mattresses bonded with our SIMALFA® debonding adhesive can now be completely returned to the raw materials cycle. The most important thing is that our adhesive is designed in such a way that the foam layers of the mattresses can be completely debonded from each other again. This process has the advantage of not only making it possible to recycle the mattress in the traditional way, but our SIMALFA® adhesive even makes it possible to upcycle the raw materials. SIMALFA® has always been at the forefront in developing foam bonding adhesives. With our new SIMALFA® debonding adhesive we just did it again.

Leading Innovative Foam for environmental requirements

As the historical leader in the manufacturing of cellular rubber foam, INTEREP’s DNA has always been the determination to propose technical products to fit tomorrow’s solutions. With the same strive, we introduced during last Foam Expo Europe shows in 2021 & 2022, our brand-new IN-LIF²E project which offers sustainable alternatives: by developing products using organic and recycled materials from production waste, by reducing our energy consumption and our carbon footprint, and by reducing our impact on the environmental balance. This Foam Expo Europe 2023 we will introduce two brand new IN-LIF²E products: 79-2 R20 with 20% of recycled materials and a NR foam with around 90% of non-fossil components. INTEREP: Your technical foam partner to face environmental requirements!

Leading Innovative Foam for environmental requirements

As the historical leader in the manufacturing of cellular rubber foam, INTEREP’s DNA has always been the determination to propose technical products to fit tomorrow’s solutions. With the same strive, we introduced during last Foam Expo Europe shows in 2021 & 2022, our brand-new IN-LIF²E project which offers sustainable alternatives: by developing products using organic and recycled materials from production waste, by reducing our energy consumption and our carbon footprint, and by reducing our impact on the environmental balance. This Foam Expo Europe 2023 we will introduce two brand new IN-LIF²E products: 79-2 R20 with 20% of recycled materials and a NR foam with around 90% of non-fossil components. INTEREP: Your technical foam partner to face environmental requirements!

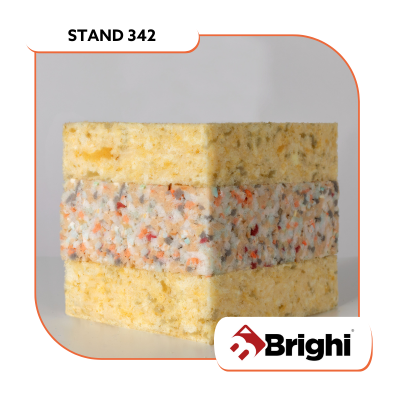

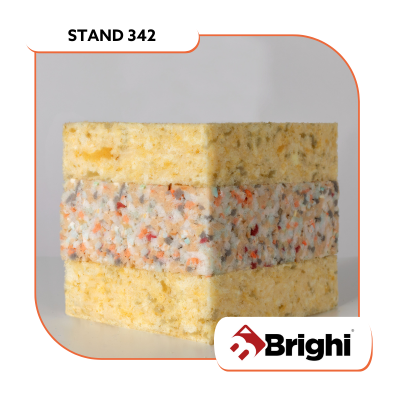

How our rebonded foam machine can boost sustainability

FA-400 is the production line for rebonded foam blocks, using foam scraps or wood pulp. With this machine, it is possible to create blocks of different densities, which can be used in various industries. The main advantages are that you can fully customise your own rebounded foam, create your unique formulation for brand differentiation working with our chemistry division on how to reduce the consumption of chemicals, and cost reduction in raw material by replacing the virgin with recycled material and zero-cost in transportation and waste disposal. Plus, it is a high-quality product with a high precision dosing system, homogeneous blending, automatic setting adjustment, and electronic storage of recipes with a quick ROI (average 12 months).

How our rebonded foam machine can boost sustainability

FA-400 is the production line for rebonded foam blocks, using foam scraps or wood pulp. With this machine, it is possible to create blocks of different densities, which can be used in various industries. The main advantages are that you can fully customise your own rebounded foam, create your unique formulation for brand differentiation working with our chemistry division on how to reduce the consumption of chemicals, and cost reduction in raw material by replacing the virgin with recycled material and zero-cost in transportation and waste disposal. Plus, it is a high-quality product with a high precision dosing system, homogeneous blending, automatic setting adjustment, and electronic storage of recipes with a quick ROI (average 12 months).

Reminder...

To access all of these eco-conscious technologies face-to-face, you must pre-register for your free pass.

Sustainable travel recommendation

We have partnered with Trainline and stand by their 'I came by train' sustainable travel movement to help fight climate change. Switching your journey to the train is one of the best things you can do to lower your CO2 emissions. Book your ticket and see how switching your journey to train contributes to a greener world.